Upgrade for airsoft AEG weapons

This article was created not only as a response to increasingly and frequently asked questions from our customers, but it also enables us to eradicate and rule out of certain rumours which prevail in the Czech airsoft community. You know it - someone can read an article somewhere and without thinking whether it is possible or not, then share this innacurate information among other people who are interested. A frequently reported untruth can eventually become the truth.

From the outset we would like to point out that we definitely do not make patent to the thoughts and all the information which we have provided below. It is based not only on our knowledge but also on the experience of our foreign colleagues and friends too.

The possibilities, variants and configurations to improve weapons is really large. In the first place you must decide if you will choose economical option which will change only less quantity of strictly necessary parts or if you will choose a variant which is more complex and expensive. The final performance can be similar for both versions but the basic cheaper parts left on the cheaper alternatives - or newly installed cheaper parts of lower quality - will be worn out faster. This causes the need to frequently dismantle the weapons and some cheaper parts you will have to sooner or later replace again - this simply means an optimum upgrade is performance while maintaining reasonable life of parts.

The best option is a comprehensive upgrade with the appropriate components for specific level of spring. It is certainly greater one-time investment mainly by using only quality components but for the long term it is surely the best choice. The gun then achieves the best performance and adequate service life of internal parts which are matched to one another.

Lately more and more frequent requirement is also the gradual upgrade when with the every service of weapon (eg. at service maintenance) is replaced at least some of the weakest parts and then subsequently increase the lifetime of internal mechanism and possibly performance of weapon. The entire process is definitely more time consuming but for gun it is better than the first mentioned variant (performance at the expense of lifetime).

In the following article we will demonstrate what is the upgrade for AEG ...

Spring

It is basically the main unit of power which participates in the greatest degree of power/energy of airsoft gun. Their marking is different by specific manufacturers and destination but the names most often begin with letters M and SP. As a general rule that is the number after the letter indicates the theoretical muzzle velocity which is specified in m/s. For example with spring M120 (of course - for correct alignment weapon) should be able to reach the muzzle velocity of 120 m/s. Sometimes the spring stiffness is indicated by a percentage. The number in this case means by how many percent the spring is stronger than the elementary spring. In general we can say that marking by a percentage is very confusing and complicated.

The important but often neglected factor is the real stiffness of spring. Because there is no standard or generally respected characteristic. Due to this reason the majority of spring manufacturers it is possible to measure the real stiffness of spring from one to two levels higher than is indicated on the package. Logically this may cause problems after cocking the weapon when the configuration is dimensionally set for a certain load but the reality is completely different, so there is a more unforeseen pressure on all components, consequently leading to higher wear and damage.

In our service we measure the real stiffness of each and every spring which we install. We take into consideration the range of spring stiffness of Systema brand which was on the market first and therefore in our opinion to identify at least some standard. These springs achieve the realistic performances and labels on packaging corresponded sense that spring M120 = 120 m/s, M150 = 150 m/s etc. It absolutely does not make sense to play the game like: "I have a gun with spring M120 but the power of my gun is 145 m/s! Hey I am a great man."

Surely you have heard from someone that some brands of springs are better than others and weapons with them achieve greater performance. Again this does not make sense, because it is always about comparison of the wire diameter, material, method of winding and number of turns. It is simple, it is not possible to make something more from a spring and this is the reason why it is more important that the realistic stiffness of spring is an indicated parameter from producer. Also keep in mind that each spring, sooner or later, will weaken and stabilise at a lower level (mainly for stronger types). Also it makes no sense to buy an expensive spring. It is far better to replace the spring once per every two years for a new one that will not be "tired" than to spend money on an unreasonably expensive product.

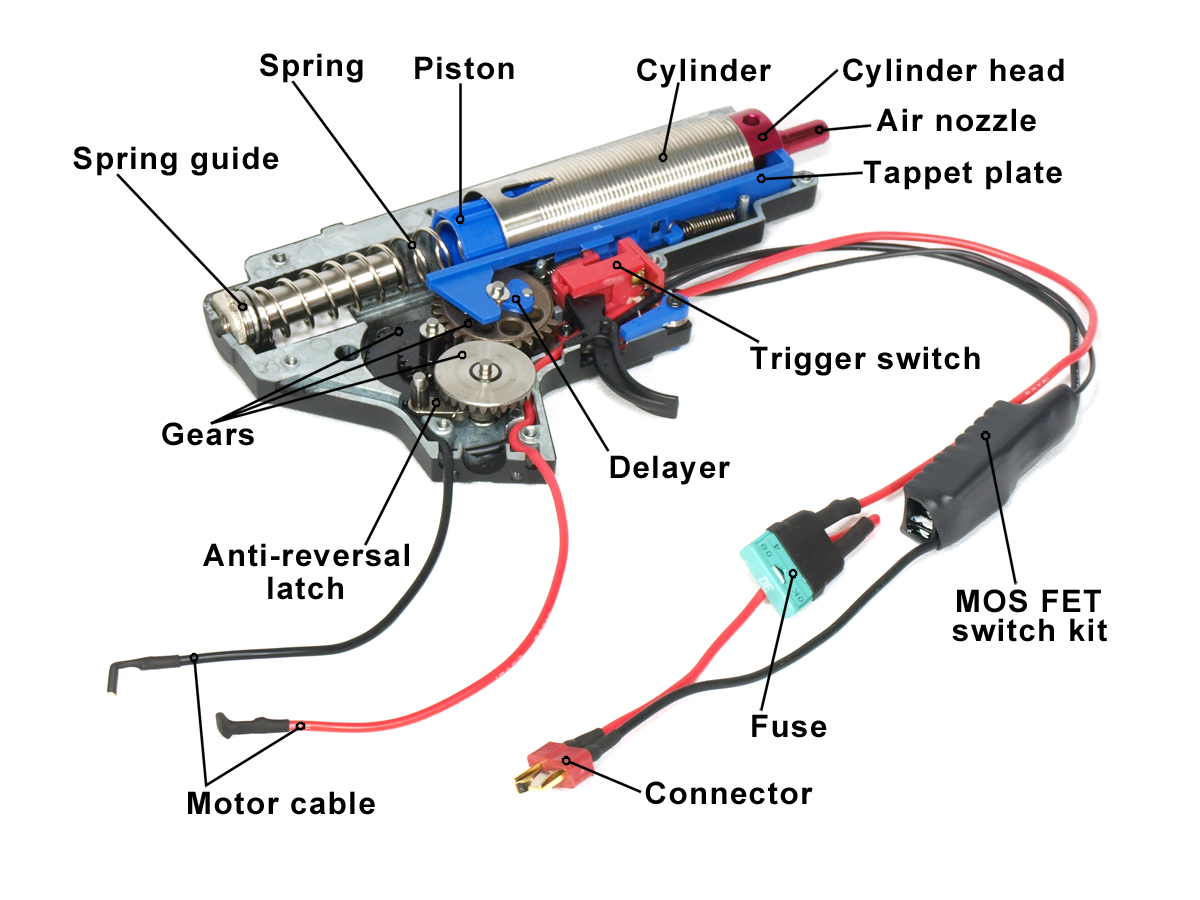

Cylinder set

Other important components of airsoft guns which determines the performance and its stability is a cylinder set. This consists of a nozzle, cylinder head, cylinder and piston head. If it Is poorly functioning or a leakage,even the strongest spring will not help you.

We also want to emphasise that it is not the best choice, especially for cylinder set, to combine large amounts of different brands and manufacturers. It is mainly for common incompatibility and therefore for us has proven the cost-effective variant with the large variety of components from brand SHS with whom you can get great results for a very good price.

The separate category are BU (Bore Up) sets, which are characterized by a slightly larger capacity and different dimensions of parts (therefore not be combined with conventional types). Due to precision and technical solutions is possible to get the largest performance increases over the realistic stiffness of the spring. With superior quality is renowned mainly NBU sets from the Japanese company Systema.

Nozzle

Some parts from cylinder set such as nozzles are usually specific for its length or shape for a specific type of weapon series. During the upgrade it is quite usual to modify and shorten the nozzle to the required length, which is often different then dimension of parts supplied from the manufacturer. Regarding this reason a nozzle with double O-rings are not suitable - it is difficult to modify it, they often disintegrate.

Cylinder heads

The cylinder heads differ in their shape, position or length of the exhaust and most are labelled according to the type of gearbox or weapons, for which the part is intended. The basic heads are mostly made from plastic with a metal exhaust, variants for upgrade are mostly from aluminum or stainless steel with a different number of O-rings on the circuit. Another important factor is the solution of the impact rubber, which may be flat or in the form of a cone. We definitely do not recommend using the heads which just have a simple O-ring on the impact side. It will soon be destroyed under the blows of the piston head and blows of metal on metal will not bring a good result.

Cylinder

Cylinders have the same length for most AEG weapons (although there are a few exceptions such as SR25, PSG1, L85, etc.) and they differ only in the capacity of air, which is affected by a hole in the cylinder. The suitability of the cylinder is dependent on the length of the inner barrel and eventually on the strength of the spring being used - for extra strong springs cylinders with higher capacity are used respectively as cylinders without holes. As well as other parts, we can find here the main division according to the materials. Aluminium with anodized finish, brass cylinders, chrome-plated, nickel-plated or completely made from stainless steel. Other properties can also be an external adjustment of cylinder walls. The basic cylinders are smooth, the better ones are already ribbed or longitudinally fluted mainly to enable better heat dissipation.

Piston head

The most universal use has piston head. We can say that in every AEG is possible to use same type of head, of course with respect to the impact area of the cylinder head. Piston heads are made with one or more O-rings. The most oftenly used material of upgraded head is a metal (aluminum), but there also exists certain lighter types of plastic heads which are suitable for the weaker types of springs. Every good piston head should be provided with axial bearing for smooth rotation of the spring in the piston.

Spring guide

It is used as a part which is fixing and leading spring to the right place in the gearbox. The most elementary type is made from plastic. Next variants are often made from plastic with base of alloy or stronger completely made from steel. Some models are equipped with axial bearing and the best, as rotational from SHS brand, offer also steel rotating body.

The spring guide is good to change depending on the stiffness of the spring or on requirement of lifetime. By influencing the compression and torsion of spring leads to transmittion of forces on the spring guide and if it is made from plastic, it can easily break and deflect. If the spring guide and piston head have no axial bearings then it can often lead to spring breaking from the influence of twisting.

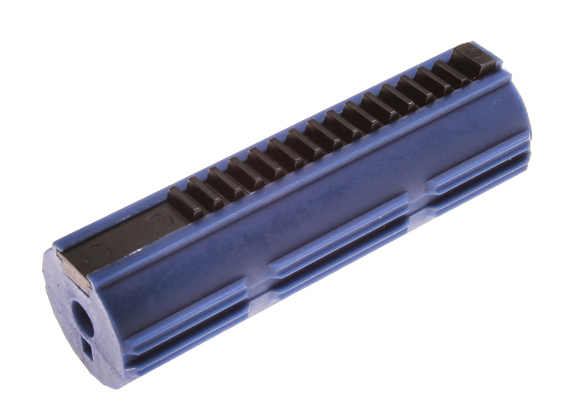

Piston

Nowadays, is practical for upgrade not to use plastic or aluminum piston, as was necessary in the past. On the market for several years has been an ideal solution - it is a classic blue piston from SHS brand, which combines lightweight polymer body, completely steel toothed comb and at a great price.

Pistons are still being manufactured with half ridge but we believe that they have become outmoded. The handicap is a smaller surface of teeth and less mechanical resistance due to the construction. On the current market exist many powerful motors and batteries, so you can even use conventional piston with full teeth and standard gear of wheels which will work well on the strongest springs for a long time without problems.

It does not make sense to use pistons which have only a few metal teeth and the rest of teeth are plastic - it is already outmoded too.

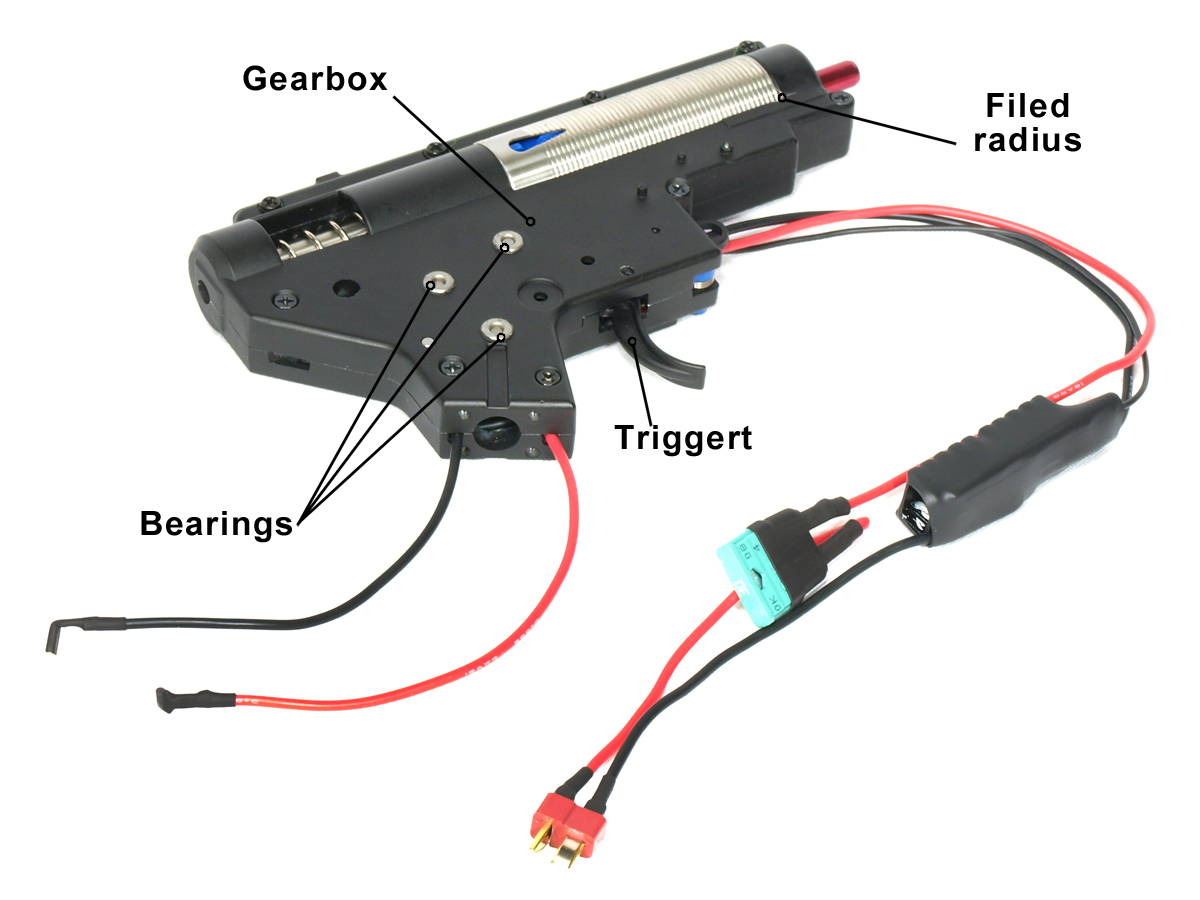

MOS FET, switch contacts, electrical installation

The majority of weapons in the basic model has switching circuit using conventional trigger contacts or microswitch. Every time you press the trigger between contact skip electric arc. It gradually burns touchpad contacts and they eventually become electrically non-conductive (gun is dysfunctional). This solution is not perfect, and we recommend retrofitted electronical installation by MOS FET set. This solution will guarantee that you will never have to solve the problems with damaged or non-conductive contacts of weapons - this solution we recommend for weapons with basic spring and it is very importat for weapons with extreme springs. MOS FET for switching also slightly higher rate of fire, shortens the delay after you press the trigger and saves battery power.

We can find a huge amount of electronic switching kits we can find on the market a huge amount. Some of them have integrated various extensions such as the engine revolution control, motor brake, programmable modes (semi, burst, auto), battery undervoltage monitoring, etc. However, it is at the discretion of each person whether it is worth investing large sums of money for elements eventhough you do not use them. Probably the biggest pioneer in this market is ASCU (Airsoft Smart Control Unit) from Airsoft Systems company. Of course these modern electronics allow programming of shooting modes, protects the battery against excessive undercharging, can provide realistic function of trigger, detects problems in the gearbox,when combined with ASCU Hop-Up chamber it will ensure detection of an empty cartridge and will completely change the function of a mechanical shooting interrupter, so the engine brake finally get some usage.

When you upgrade every AEG weapon it is well worth replacing the original wire for a wire of higher quality. They can be easily recognized - pure copper or copper with nbsp; tinning, well flexible beam of the high number of wiring harness, wire cross-section of 1 - 1.5 mm, flexible and heat-resistant silicone insulation. Some technicians tend to use cables which are too strong, but they forget that determinant of wire resistance is mainly its length - even here, everything in moderation.

We definitely recommend to replace the connectors for better and more modern ones - ideal types are gilded with lower resistance. Connectors for modellers T-Dean have became the standard for the upgrade of AEG weapons because they handle higher electrical currents better, are for a competitive price and are very user friendly. Outdated, but the most common connectors are still Tamiya and Tamiya mini.

Gears

The most recent trend are revolutionary gears from brand SHS with excellent ratio of quality and price. The manufacturer offers a whole range of sets - from the fastest gears to the slowest types of piston with half teeth. From such offers you must choose yourself, it is just to correctly determine gear ratio according to the spring, motor and battery. We offer more expensive gears from manufacturers Classic Army and Systema too.

Some people unfortunately still mistakenly think that high torque gears are made from different material and consequently to greater durability with use on stronger springs. But it is not true, the material used by manufacturers for upgrading gears is still the same and they change only the size of individual wheels and the number of teeth - this determines ratio of gear.

For the conversion of torque in AEG systems, gears with flat or helical teeth are used. Sets are usually completed from three separate pieces of gears. Helical gears are considered to be more durable and quieter because the teeth are smaller and they have a larger contact area. Their disadvantage is "lateral displacement" which can lead to axial loads on the radial ball bearings of gearbox, which may result to them being damaged. Helical gears are therefore necessary to be installed only with the most resistant ball bearings with a diameter of 8 mm or higher. Sets with flat gears are commonly used and probably most widespread. Their installation is simpler and a less demanding precision arrangement.

As noted above, the choice of the right gear ratio is dependent on real stiffness of spring, strength/torque of the motor and battery in use. We always recommend to compose the kit to achieve "the healthy cadence", i.e. approx. from 14 to 20 rounds per second. Lower and higher cadence - than recommended - is for each AEG weapon potentially dangerous and it will lead to wear and tear of internal parts. However, some customers attach great importance for a higher rate of fire, because it will provide greater firepower of their weapons.

Anti-reversal latch

As the name suggests, this piece together with a spring prevents unintentional release of gears after each shot. On most anti-reversal latches chipping of the edges may occur but more often a problem is cracking of spring which is pressing latch on the bevel gear.

Delayer

It is a small rounded piece or teardrop shape made from metal or nylon. Delayer is for clicking on the piston wheel, is not stressed, so that its most important properties are mainly the shape. The shape of the delayer along with the shape of a flag on a hanger of feeder affects the operation of the nozzle and the duration of its stay in the hop-up chamber respectively "open" time of the chamber. Its use usually solves the problem with poor feeding from magazine during higher cadence of weapon.

Tappet plate

It is the plastic piece which move with the nozzle in the chamber. Moves foward in slots of gearbox which mostly provides tension on the spring and moves backwards provides tappet plate to attach to the piston gear. If the nozzle in chamber does not move/feed and the gears are still turning, it is probably the problem with this part or its spring. For each type of gearbox is usually specific shape and length of tappet plate.

Bearings

Normal airsoft gun as a standard contains 6 radial bearings which are used for fixing axis of gears to prepared holes in the gearbox with diameters 6-9 mm according to the type of skeleton. Bearings besides dimension are divided to classical plain bushes (of various types of metal or nylon) and ball bearings which have a smaller rolling resistance. Disadvantage of ball bearings is less mechanical resistance and risk of damage, particularly for smaller types of bearings (diameter 6, 7 mm) and stronger springs and helical gears.

Hop-up rubber

Hop up buckings have a really large amount of various qualities, characteristics and price ranges on the market . Every manufacturer has slightly different characteristics, different dimensions or used materials. Another important factor may be the shape of the pressing protuberance or the size and material of the pressing roller. Everything from these parameters have great influence on its performance, stability of performance, performance of hop-up effect, etc.. - ultimately the accuracy of gun.

This "consumer" part is pushed onto inner barrel in the hop-up chamber. The wrong choice of rubber bands or incorrect installation can be quite simple to lose more than 10 m/s from the power of weapon. No responsible technician would tell you in advance what will be the best rubber bands for a specific weapon and upgrade. It is necessary to test several rubber bands and keep the best one.

The rubber band should be changed periodically, ideally after every season. The material of rubber band becomes wears, grows older and loses its properties. In the case of change of the inner barrel, it is usually good or needs to replace hop-up rubber band.

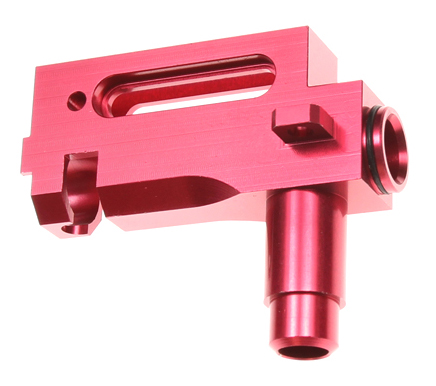

Hop-up chamber

This relatively important part connects gearbox to the barrel and connects the feeder of balls from the magazine. For some weapons it is possible to keep the original chamber even in case of large upgrade. From our experience it is a better option than risking untested products from other brands where it is not guaranteed compatibility, which can cause unsolvable problems.

Most often exchange of chambers is performed at weapons type M16/M4 for which is possible to replace the original plastic chamber for metal (alloy castings and CNC workpieces from duralumin). it is possible to lean front part of gearbox by the chamber, thereby will delay danger of possible fracture. This already standard treatment has also consequently prevent rebouncing of the chamber during firing and much more stable performance. In our upgraded Custom series have proved chamber from the SHS brand.

Often exchange of chambers is performed on weapon types AK. But it is not such a simple "operation" as the series of model M16/M4, but is still less problematic than in other airsoft replicas. With exchange of the chamber you can obtain but also much more to lose.

Motor

Motor is basically the main driving force of every airsoft electric gun. For this reason, the AEG guns do not need to cock and for each shot you can simply pull the trigger on the "semi" or "full auto" mode with relatively high cadence. These DC electric motors use the most common NiCd and NiMH rechargeable batteries of different capacities with voltage 7.2V - 12V and or the modern Li-Pol battery with 7.4V - 11.1V. It will spin the motor and its torque can be transferred from sprocket to axis to further gears in the gearbox.

The motor axis are divided to types with "O" shape where the pinion is usually pressed and "D" shape where the pinion is secured by the small bolt for imbus. Motors are divided to three types according by the length of axle and then according to their parameters for basic, high-speed, hight-torque, extremely strong, etc.

Among some people is widespread the wrong idea that the longer motor is more powerful than short. Logically, this is not true because the difference is only in the length of itself axis. Appropriate choice of the engine length is dependent on the type of gun and the choice of its parameters for the final configuration of the entire internal assembly and use of resources.

Cut off lever

Cut off lever is the other one small piece in gearbox which basically does not wear and tear due to force of spring. The basic cut off lever is a metal part used for lifting/disconnecting the contacts rider. Correct function isonce per revolution of the piston gear in the case that the fire mode is on "semi".

If someone prefer shooting by "semi" mode, than we recommend installing a steel cut of lever and make modification of the trigger slider, which is accomplished by reinforcement. Otherwise it could become that semi mode will stop working because the cut off level and contacts rider will wear so they lose the necessary function. To fix it you will need to purchase this little piece along with contacts and "semi" re-tune again, which is a very time-consuming job.

Selector plate

It is a flat plastic piece on the outside of the gearbox and is determined for transmit "movements" from switcher of shooting mode to the above mentioned cut off lever. This piece is not stressed too much and replacement is uncommon. For each type of gearbox is usually with specific shape and length of the selector plate.

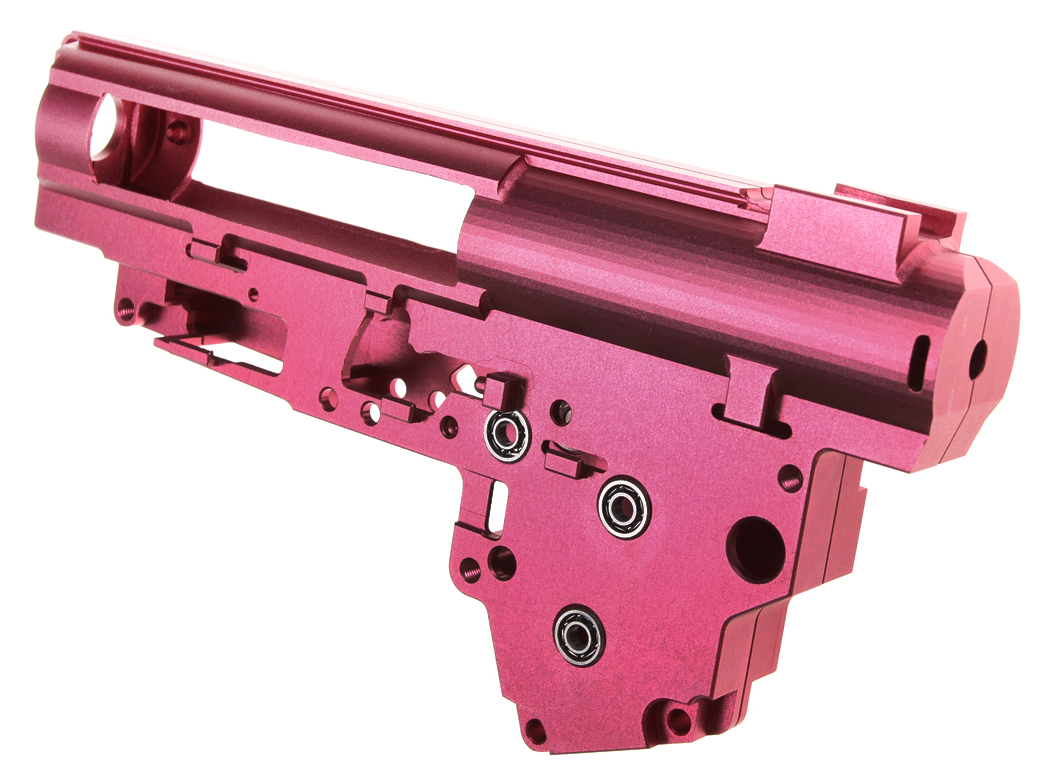

Gearbox

Replacing gearbox is probably the most complicated service procedures for AEG. It is basically the main box to which must gradually rearrange or insert all the necessary parts to ensure the proper functioning of AEG weapons. Standard gearbox is labelled by number or by name of the gun type as regards extension or less specific shape. Each gearbox has different dimensions and uses specific parts.

99% of the gearboxes are from metal and mostly from alloy of ZnAl or the stronger ones are made from the machined aircraft aluminium made by CNC machines. Some types of gearbox may be with stronger springs more resistant than others, this is caused by quantity of material in front of the most exposed part.

The decision about replacing the gearbox is one of those essential for high upgrade of weapons. Possibility about availability of quality and durable gearbox should be taken into account even to initial choice of weapon. Some weapons which the construction will allows are already equipped with durable gearbox which can allow for stronger springs, but unfortunately for most weapons this is not true. The availability of high-quality replacement is sometimes essential parameter for good choice of weapon to upgrade.

Barrel

The decision about exchanging the barrel for a more accurate barrel, should be one of the fundamental aspects of each upgrade of AEG. There are many types of barrels offered on the market, differing in internal diameter (6.01 to 6.04 mm), length (110-650 mm), used material, finishing and final price.

When deciding which barrel to choose, please do not take into account only inner diameter and the lowest price, because this is absolutely not the right way to success. If you want unparalleled quality, we can offer you the best variant on the market and it is stainless barrel, from the well known japanese brand PDI.

The smaller inner diameter of the barrel always logically increases demands on the quality of the bb. It is usual that during the use of bad (usually the cheapest) bb frequently clogs and blocks the barrel and sometimes destruction of other parts in the gun. That is why we always recommend using high quality and proven balls BLS, because with them we have the best long-term experience on the smallest diameter of the barrels.

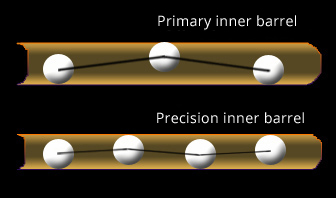

The effect of the precision barrel can be seen on the following picture which shows that from the basic barrel the ball can be fired out with high deviation from the axis of the barrel, but with precision barrel the deviation is minimized.

It is undisputed that effect of the precision barrel on accuracy of fire is higher for shorter barrels than the longer (400 mm or more). The reason is that in the short barrel the bullet has no possibility to stabilise its direction as well as in the longer barrel.

Please remember that each barrel must be cleaned regularly, because otherwise it will not help with its accuracy, used materials, even the best ammunition.

Does it make sense to install a longer inner barrel?

More and more often we meet with the customer requirements for the installation of a longer inner barrel. Maybe it is about visual appearance, because someone may be like a shorter carbine fitted with a silencer more than long rifle in a factory design. Longer inner barrel means higher accuracy and longer track to accelerate ball, therefore will improve to the better shooting properties of the weapons.

The barrel you can extend by additional silencer, external adapter or is it possible to use free space in the compensator. In the first two cases, the extension is not problem. But in the second variant you need to know how the barrel is mounted in the front part. Because sometimes it is necessary to drill a larger hole in the flash rider and then it can be the barrel inserted through

Another problem of extension is mainly based on the capacity of air that is cylinder able to deliver to the barrel. In case that the capacity of elementary cylinder is not enough to fire bb from the barrel, then the bbs will be slowed down by walls of the barrel. In a better case it will only reduce the muzzle velocity of bb, but in the worst case, the auto shooting will be very unstable and poor.

So if you are considering lengthening the barrel, then always in advance to determine which type of barrel is used in guns with the same cylinders as in yours. The capacity of the cylinder determines the location and number of holes in its body. For Bore Up sets it is inside diameter too.

Batteries

For a long time is in the minds of airsoft players that best batteries for high current draw (which require the AEG too) are the only ones that are based on NiCd technology. But development of NiMH batteries has progressed and on the market there are high quality NiMH batteries which the classic NiCD overcome easily. In the last few years, it is apparent that the NiCd technology is out of date andwill finally disappear entirely.

In the AEG weapons are used DC motors powered mostly by before mentioned NiCd/NiMH rechargeable batteries with voltage 7,2V - 12V or in modern Li-Pol versions 7, 4V - 11,1V. Each type of battery has its advantages and disadvantages, so that suitability is different.

Choosing batteries depends both on the configuration of the entire assembly and how you are limited by interior space which you need for battery. Rifle with fixed stock usually has more storage space than for example AK with folding shoulder stock. Even today you can still find individuals who solve battery saving externally. Today we have a lot of types of battery variants and from this reason this solution by our opinion is unnecessary, visually ugly, impractical and even dangerous.

We will try to briefly summarise the essential characteristics of different types of rechargeable batteries. Precise and detailed recommendations set out on a whole new article, which is already going on.

NiCd - no advantages / a lot of disadvantages ... it was simple:)

NiMH - high capacity, low internal resistance, mechanically durable, easy to clean, friendly to the gun / poor ratio of weight versus capacity versus size in compared of Li-Pol, with use of strong springs is unusable capacity of cells, high self-discharge

Li-Pol - effectively 100% usable capacity even with strong springs, very low interal resistance, cost, no self-discharge / low mechanical durable, demanding for care, very prone to damage due to overcharging and undercharging, increased wear of the motor and load of weapons

In offer of our e-shop you can find a high range of batteries from different brands. Probably the most popular brand of batteries is VB Power which manufactures battery packs of various shapes and parameters. They are a very good cells with low internal resistance imported directly from the manufacturer at an unbeatable price.

Finally two things to be aware of.

1) Please keep in mind that too much battery power means high cadence which can prematurely wear out piston, gears in the gearbox or motor. Cadence of weapon must be "healthy" see. text above.

2) The hunt for a high "C" for Li-Pol batteries for AEG guns is stupid. For example, in various discussions you can read, or you get advise to buy a powerful Li-Pol with the greatest discharge electric current (the number of "C"). The practice it means that the batteries with the high "C", there is a much more sparking between brushes of motor and commutator (if you have an electronic switcher with motor brake, then it multiplies twice). Motor therefore much more wears and its lifespan is considerably lower than you use battery with reasonable "C". Furthermore, high "C" of the battery causes a sharp spinning of gears and stretching spring, this will reduce lifetime of gears and piston. Therefore, it is always best to take adequate type with regard to the assembly of parts in gun - so this means not too weak and not too strong battery.

Finally

When you upgrade your weapons always keep in your mind that each manufacturer designs their products for maximum durability with the basic components and especially with the basic spring (although about some Chinese brands we can legitimately make doubts about this). If you will start with the installation of the stronger springs, then you always have to count with some risk and potential costs that may bring damage of overloaded component.

Lifetime of weapon with high upgrade will always be lower than the weapon with the basic spring. Sometimes it is better to install spring with one level below weaker, but install better cylinder set. In this case, you get the same performance, but more saving components in the gearbox, the motor and the battery.

Improving performance of the airsoft guns is equivalent of the "tuning" a race car. If you want to ride on top position or have an extremely high performance, range and firepower, so it will cost something to you and still can sometimes happen and you do not reach to finish. It is also important to respect the basic rules of use and periodically serviced. If you are a occasional shooter then be more interested in the life of your weapons than for high performance.

Keep in mind that any home handyman can not have such experience and facilities as a professional and quality service which get as many weapons with various complex repair or upgrade. Yes, it is even ours:).

We hope that this article has brought something new and a little bit of help to you about better awareness of upgrading of AEG and used parts. It is likely that we did not have enough to capture all aspects of the upgrade, so the article can be additionally added. In the event that you find the part which is not sufficiently or clearly outlined, so please contact us via the comments to this article or directly to email support@airsoftguns.cz where we will be happy to provide further information and recommendations directly about upgrade of your specific weapons to you.

AirsoftGuns s.r.o.

AirsoftGuns s.r.o.

.jpg)